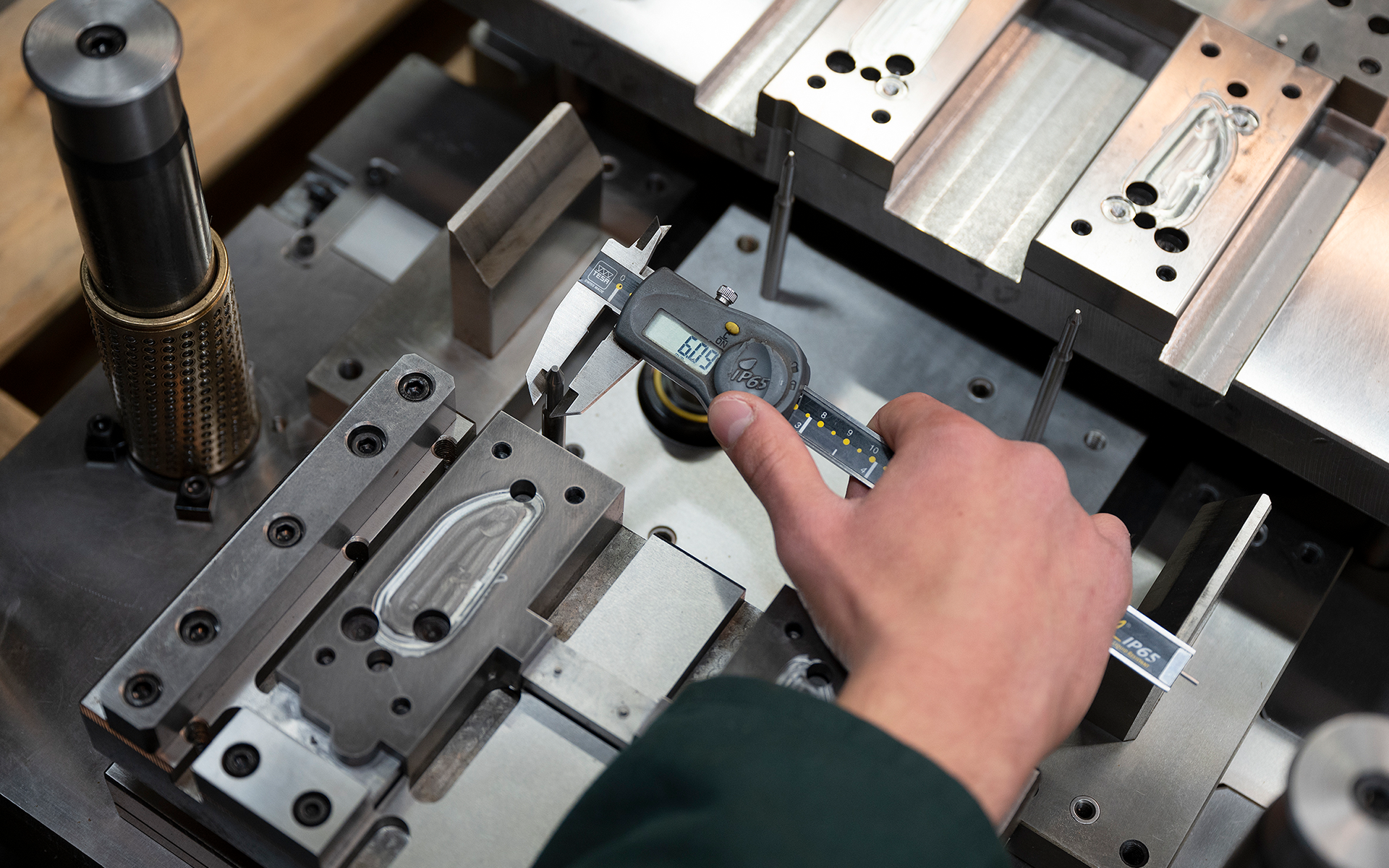

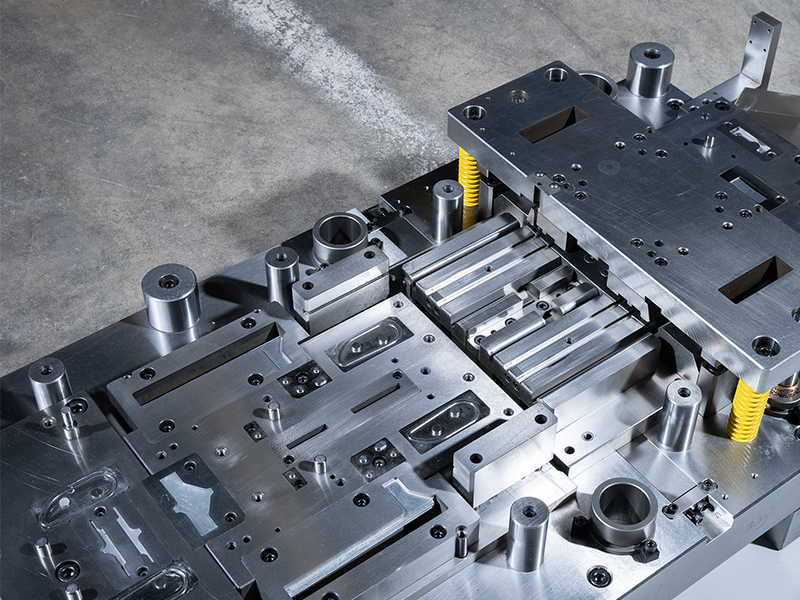

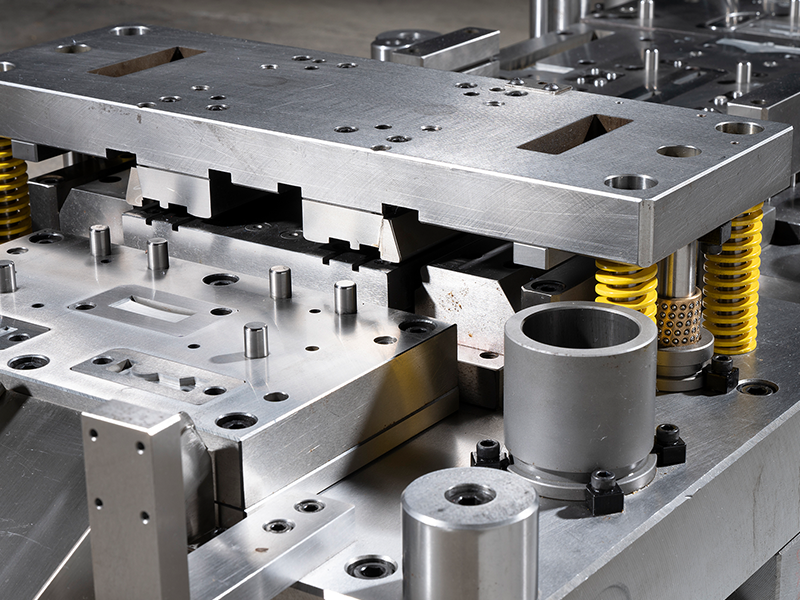

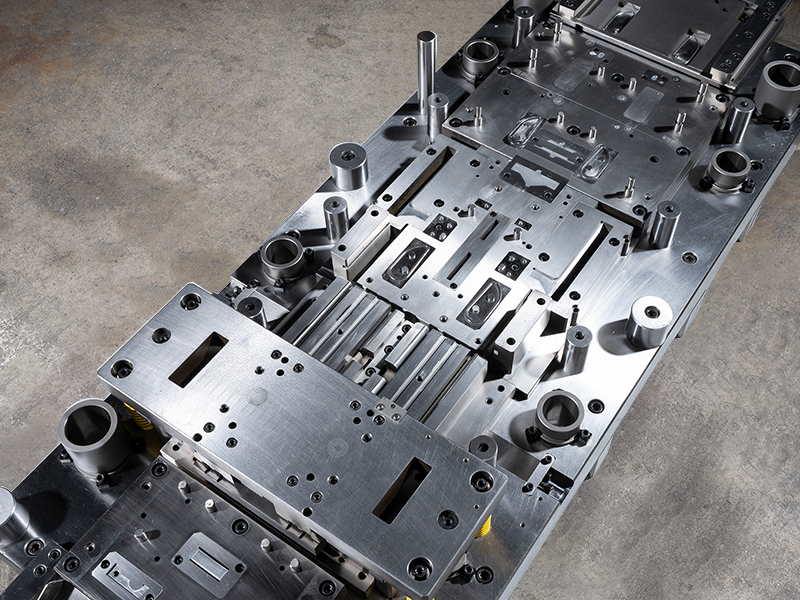

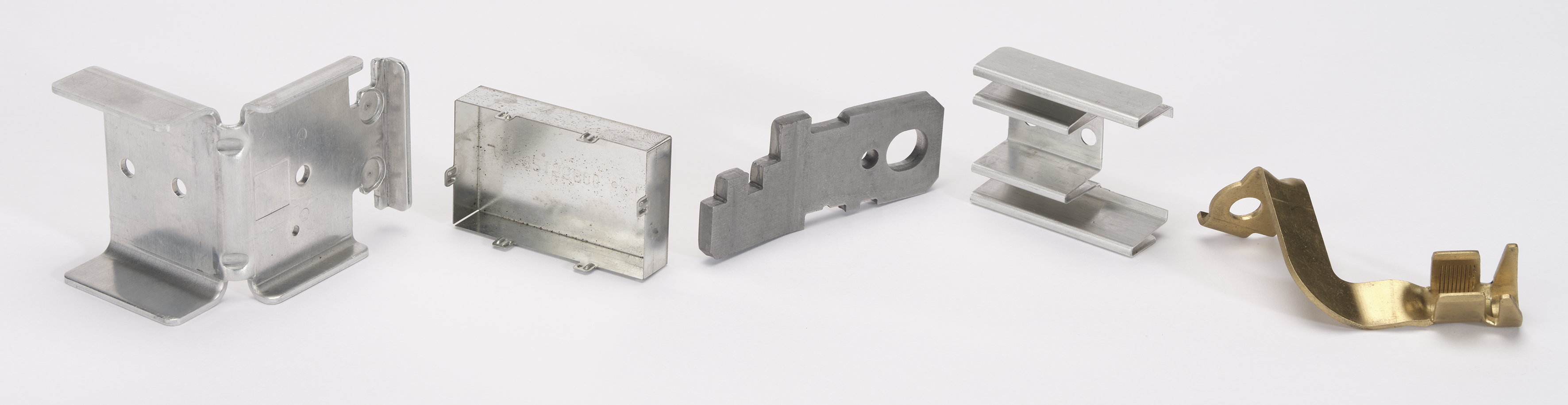

Cutting and stamping tools

From study to manufacturing, we design tools for all industries and in all types of materials (steel, carbide and derivatives).

Our strengths

Today the costing, strategy and design of our products are carried out in France.Manufacturing, adjustment and development (pacing with prior production) are carried out in our manufacturing and production site in China.

Our products, carried out and put into service for our customers, range from small tools up to 2,500mm (250 tonnes).

Some achievements

Some achievements

- All our tools are manufactured, tested and adjusted

- Delivery of initial samples for validation before commissioning on your premises

- Tools guaranteed for life in accordance with the rules of the art (excluding wearing parts and active parts)

Do you have a project?

Let’s talk about your custom cutting and stamping tool project together!